built with quality and integrity

|

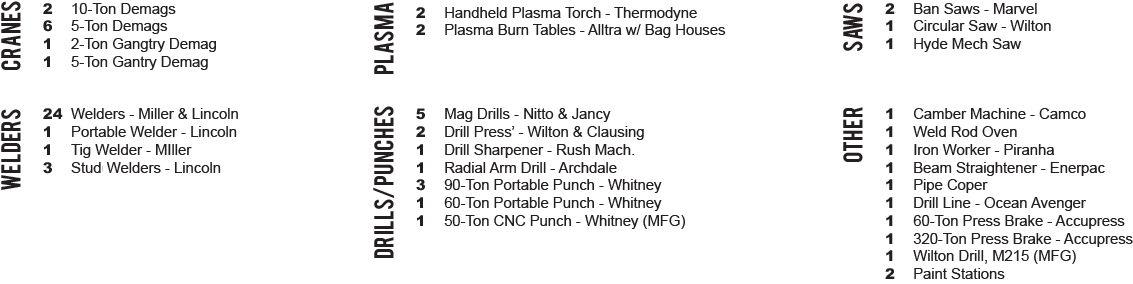

At McFarlane, we put a premium on having the finest steel fabrication equipment and facilities. Our 24,000 square foot fabrication facility is equipped to handle any project from the largest structural members to the most intricate decorative ironwork and railings. Our team is aided with advanced systems for computer-aided design, as well as cutting, sawing, drilling, and welding. Consequently, we have the capacity to fabricate large projects and deliver them on schedule on our own fleet of trucks. Our facilities also enable us to achieve the highest levels of precision and accuracy. We carefully inspect every shipment, so it's ready to erect upon delivery. McFarlane customers have come to rely on complete, timely deliveries and ease of erection.

Being a member of the American Insitute of Steel Construction (AISC) and the Central Fabricators Association (CFA), we are held to high standards which we meet and often exceed on most of our jobs. Our welders hold certifications in both SMAW and GMAW welding techniques. We have spent decades building business relationships with contractors near and far, and it shows through our testimonials just how good we are. Contact us today to see how our outstanding services can help you. |